Electric Cars: Why Manufacturers Rely on Continental Tires

How Continental tires perfectly complement electric vehicles and why it matters

Seven of the world’s 10 highest-volume producers of battery electric vehicles rely on Continental tires for their original equipment. This is no coincidence, because choosing the right tire for electric vehicles is crucial for efficiency, braking and mileage.

- E-mobility is changing the focus of tire development, with rolling resistance, mileage and interior noise taking center stage.

- The result: Continental tires are already the first choice of many electric car manufacturers.

Tesla, Volkswagen, Mercedes-Benz, Porsche, Ford and the Asian carmakers Kia and BYD all have one thing in common: as OEMs, they rely on Continental’s technology expertise in their electric vehicles. Continental now equips seven of the world’s 10 highest-volume producers of electric vehicles with tires.

“The first thing you need to know is that there is no single tire for electric vehicles. This is because fully electric models are now available in almost all passenger car segments, and increasingly in public transport as well. The selection ranges from mini electric vehicles, such as bubble cars, to small and mid-size cars, to SUVs, high-performance sports cars and electric buses. “We develop tires for a wide variety of applications – not for specific drive types. At its core, tire development is about achieving the best possible combination of safety, efficiency and comfort,” explains David O’Donnell, head of Original Equipment Tires. Andreas Schlenke, head of Benchmarking, Portfolio and Pre Tireline Development, adds: “For electric vehicles, in addition to braking performance and handling, the key properties are mileage, interior noise and rolling resistance. For more than a decade, we have been developing our existing portfolio to meet the requirements of all electric vehicles. Today, almost all of our current products are designed to be used on electric cars and to optimize their range.”

It therefore makes sense to always choose the tire whose properties are best suited to the specific requirements of the vehicle type and thus also those criteria that are particularly important for electric cars, such as range or interior noise.

David O'Donnell, head of Original Equipment Tires at Continental:

"We develop tires for different electric vehicles and their fields of application – regardless of whether they are small cars for city traffic or off-road SUVs. We are proud that so many manufacturers around the world are equipping their vehicles with our premium tires – this is proof of our development expertise and the premium quality of our tires.“

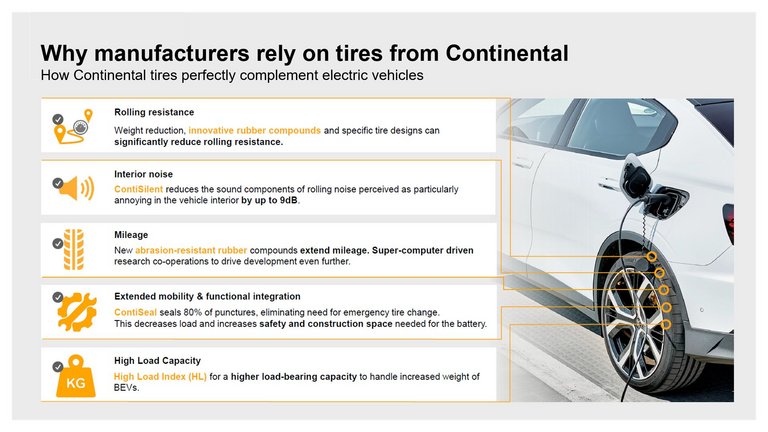

Key challenges and Continental solutions at a glance:

Challenge: weight

Solution: higher load capacity

On the design side, the demands on tires are also changing in the course of e-mobility – for example, with regard to increased vehicle weight as a result of the installed battery units. The ID.3, for instance, by definition a small car, weighs a considerable 1.8 tons. It is therefore particularly important to choose tires that are adapted to the increased weight. Since 2021, Continental has been producing the first passenger tires with the new HL load index code. At the same inflation pressure, these tires have a load capacity that is up to 10 percent higher than those with the previously common XL standard. This means that narrower tires are also able to carry higher loads. And that is a plus for electric vehicles, whose contact area with the road has an influence on another important criterion: range.

Challenge: range

Solution: rolling resistance-optimized tires

Anyone who drives an electric car will have asked or been asked the question: how far can the car travel on a single battery charge? Although this is primarily a matter of battery capacity, motor energy efficiency and driving style, the tires also play an important role. After all, a tire’s rolling resistance and aerodynamics have an influence on the vehicle’s energy consumption. The general rule is that lower energy consumption is sustainable – regardless of the type of drive system. In the case of electric vehicles, better energy efficiency leads to longer ranges; in the case of vehicles with internal combustion engines, it leads to lower fuel consumption and thus lower CO2 emissions. If rolling resistance is reduced by 1 kg/t, the range of an electric vehicle is increased by around 3 to 4 percent. Generally speaking, tire developers at Continental have been placing particularly high value on continuously reducing rolling resistance for many years – because this creates additional range. For example, with the aid of a series of design measures, the developers have succeeded in improving the rolling resistance of an EcoContact 6 specially developed for Ford to such an extent that it is now more than 15 percent above the requirements for the EU tire label class A.

Challenge: interior noise

Solution: ContiSilent

An important issue for electric vehicles is the noise generated by the tires. This is because rolling noise and air turbulence are clearly audible, especially at higher speeds.This can be particularly annoying in the interior, where the noise of the tires seems louder due to the absence of engine noise. ContiSilent technology, which was first developed for passenger car tires back in 2016, is able to reduce the sound components of rolling noise that are perceived as particularly intrusive by up to nine decibels. A special layer of polyurethane foam absorbs vibrations from the road, reducing the transmission of noise to the body and into the passenger compartment. ContiSilent is compatible with all commercially available rims and does not affect vehicle performance, fuel consumption, load capacity or top speed.

Challenge: full torque

Solution: durable design and robust rubber compounds

One of the special features of electric drive systems is torque: during drive-off, the tires have to produce full torque, or “instant torque,” in a matter of seconds. The increased load as well as the higher torque can also lead to greater tire wear. Good durability and low tire wear are therefore important. The aim is to enable the efficient operation of all vehicles – regardless of the drive type. Manufacturers of electric vehicles therefore have good reason to choose tires from Continental. With their technological expertise, the company and its employees are making a valuable contribution to safe, sustainable and future-proof mobility.

Seven of the World's Ten Most Successful E-Vehicles Manufacturers Rely on Continental Tires Ex Works

Continental continues to expand its position with tires for fully electric vehicles. In 2021, for example, seven of the ten highest-volume manufacturers of electric vehicles worldwide relied on the high technological expertise of the premium tire manufacturer as original equipment. These included Tesla, whose models are all equipped with tires from Continental ex works, Porsche, and Mercedes-Benz. But Asian manufacturers, such as KIA and BYD, and American vehicle producers, such as Ford, also rely on tires from Continental as original equipment for their electric vehicles...

Read the press release here.