Continental Uses Vacuum Technology to Study Tire Wear Particles

- Continental continues to reduce tire wear through innovative technologies, intensive research and active participation in industry initiatives

- ADAC data confirms its progress: Continental tires abrade significantly less material than the average competitor product

- New analysis method detects even the finest wear particles at the moment they are generated

- “Data on the quantity, size and structure of particles allows us to optimize tire designs and rubber compounds even more precisely – without compromising on safety or performance,” says Dr. Matthias Haufe, head of Material Development and Industrialization at Continental Tires

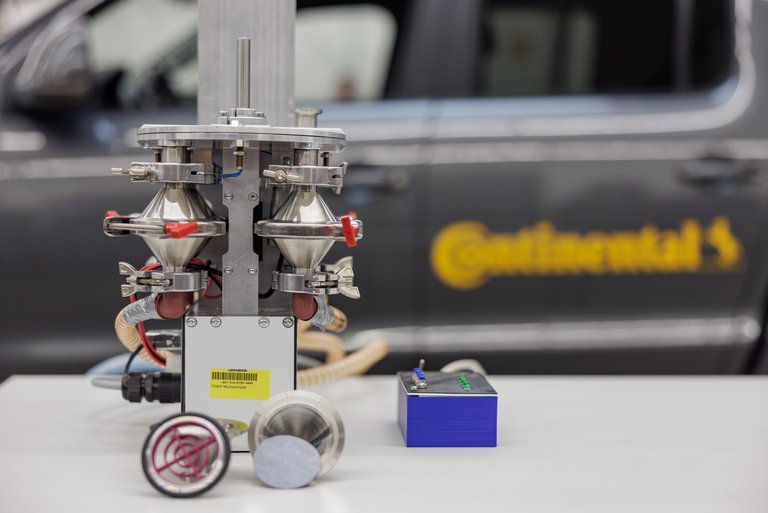

Hanover, Germany, November 17, 2025. Continental is pushing forward with efforts to reduce tire wear by using innovative technologies, carrying out cutting-edge research and actively participating in various industry initiatives. The result: demonstrably lower environmental impact. According to a recent ADAC analysis of 160 tested products, Continental tires abrade 11 percent* less material than the average competitor tire – clear evidence of the effectiveness of Continental’s technologies and measures. A key driver of this progress is intensive research. For example, Continental has partnered with the Technical University of Braunschweig to develop an innovative method for analyzing tire wear. This method uses a specially adapted vacuum device mounted behind a drive wheel, which – together with advanced particle sensors – enables the detection of even the finest airborne particles behind the wheels and at other points on the vehicle.

This measurement technique was developed as part of the recently completed research project OLRAP (“Online Analysis of Airborne Tire Wear Particles at the Point of Origin and Differentiation from Other Sources”). The insights gained feed directly into Continental’s tire development, enabling targeted improvements. “Data on the quantity, size and structure of particles allows us to optimize tire designs and rubber compounds even more precisely – without compromising on safety or performance,” says Dr. Matthias Haufe, head of Material Development and Industrialization at Continental Tires. This not only advances our technology but also prepares our products for upcoming regulations like the Euro 7 standard, which will introduce limits on tire wear emissions in the EU starting in 2028.”

OLRAP research project: new method for online analysis of tire wear

Funded by the Lower Saxony Ministry of Science and Culture, the OLRAP project provides valuable insights into the properties of tire wear. A specially equipped test vehicle, designed by Continental for real-world driving conditions, was used in the study. The vehicle was fitted with a specialized vacuum device behind a driven wheel to collect particles as they were emitted. This allowed researchers to determine the origin of the particles – whether they came from the tires, road surface or brakes. Particle measurement instruments developed by TU Braunschweig were mounted at various points on the vehicle, including directly behind the wheels, to collect detailed, time-specific data. These measurements were correlated with factors such as driving dynamics, road surface conditions and weather – an essential step toward scientifically accurate tire wear analysis. Using a newly developed multi-sampler device, researchers were able to collect samples related to specific driving events. In the lab, they compared particles gathered during cornering versus straight-line driving.

“The highly complex experimental setup, with simultaneous measurements at different points on our test vehicle, generated vast amounts of data, helping us to better understand tire wear,” says Dr. Benjamin Oelze, head of Tire Wear Testing Development at Continental Tires. “We identified clear correlations between particle concentration and speed profiles, as well as the impact of high longitudinal and lateral acceleration on tire wear.” These findings could help optimize traffic flow and vehicle driving profiles to reduce emissions and improve environmental sustainability.

Researching less tire wear – without compromising on safety or performance

Continental has long been committed to research projects focused on tire wear. The tire manufacturer co-chairs the Tire Industry Project (TIP), an initiative that studies the environmental impact of tires throughout their life cycle. Continental was also the only tire manufacturer to take part in the RAU project (“Tire Wear in the Environment”), an initiative by the German Federal Ministry of Research. This project developed a filtration system capable of capturing up to 97 percent of solid particles beneath storm drains.

A tire’s primary function is to transfer vehicle forces and ensure sufficient grip on the road. This grip is achieved through friction, which inevitably leads to wear on both the tire and the road surface. A certain level of tire wear is unavoidable if safety-critical features – such as wet braking performance – are to remain uncompromised. Studies show that driving style and road conditions influence tire wear up to three times more than tire design. While these factors are largely beyond the control of tire manufacturers, tire design is not – and that is where Continental focuses its efforts. For example, the EcoContact 6 tire line generates 30 percent less wear per kilometer and delivers 20 percent more mileage compared with its predecessor – a measurable improvement in environmental impact and efficiency, achieved without sacrificing safety or performance.

*ADAC: Allgemeiner Deutscher Automobil-Club, https://assets.adac.de/image/upload/v1749035559/ADAC-eV/KOR/Text/PDF/33478_dppcxx.pdf.

Henry Schniewind

Head of Global External Communications

Continental Tires