Continental Invests in New Recycling Technology to Recover Raw Materials from Waste Rubber

- New pyrolysis technology enables recycling of complex rubber compounds and reduces need for fossil raw materials

- Continental’s group sector ContiTech acquires exclusive patent rights for thermal purification process

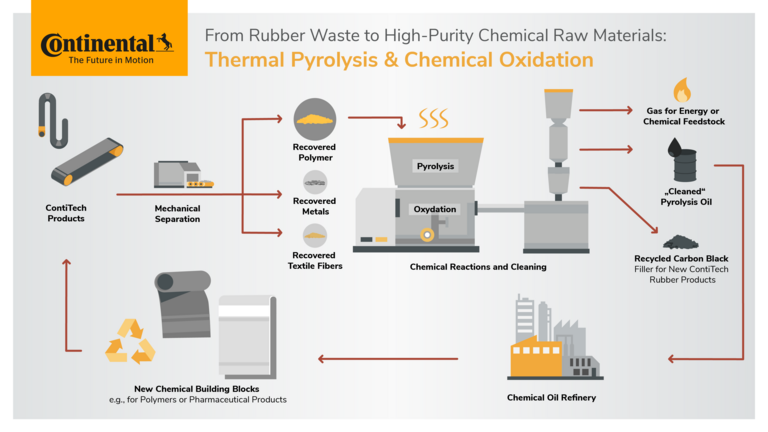

Hanover, Germany, September 3, 2025. With the acquisition of an exclusive patent family and the commissioning of a newly developed pilot facility for the production of purified pyrolysis oil, Continental is harnessing the industrial potential of pyrolysis technology for the first time and laying the foundation for recycling complex rubber compounds on an industrial scale. The technological solution employed by the group sector ContiTech is designed to recover high-quality raw materials from waste rubber and systematically replace fossil resources.

The technology is based on a thermal process in which waste rubber is broken down into its basic chemical components. Among other things, this produces a high-quality oil that is comparable in quality to fossil crude oil and can serve as a basis for new rubber and plastic products in the future. Originally developed by British start-up LowSulphurFuels, the new purification facility uses a special method to process this oil for industrial use.

“With this technology, we’re closing a crucial gap in the circular materials economy: we’re able to recover high-quality raw materials from rubber waste, which we can then feed back into the chemical material cycle to create new products without relying on crude oil,” says Dr. Michael Hofmann, Chief Technology Officer at ContiTech. “We’re thus demonstrating how innovation can become the driving force behind sustainable industrial processes – and how a previously untapped raw material cycle can be made economically viable.

New possibilities for hard-to-recycle rubber products

The recycling of rubber has always been a major challenge for the industry. Once vulcanized, the chemical structure of the material changes permanently and its original components, such as rubber, carbon black and additives, can no longer be easily separated from one another. Conventional mechanical and chemical methods quickly reach their limits. Pyrolysis offers an alternative approach: through controlled heating in a low-oxygen environment, the material is thermally broken down into its basic components. Among other things, this produces a gaseous energy source, recovered carbon black and a high-quality oil that is similar in composition to fossil crude oil. The latter in particular offers great potential for reuse in rubber and plastic production. The reason why pyrolysis has had limited use in rubber recycling to date is mainly due to the complexity of the process and the high quality requirements placed on the recovered products. Only through technological advances in processing – especially in the purification of pyrolysis oil, as made possible by ContiTech’s new facility – has industrial use become economically and technically feasible.

Complex rubber products in particular, such as food-grade hoses and rubber-metal composites with various additives and complex material structures, have so far posed a major challenge in terms of recycling. The materials experts at ContiTech see purified pyrolysis oil as a promising solution for reintegrating these product groups back into the material cycle in the future.

By acquiring the patent and commissioning the first pilot facility, ContiTech is sending a strong signal for sustainable innovation. With more than 150 patent applications filed and around 250 patents granted last year, it is also underlining its innovative strength and commitment to more sustainable industrial solutions. ContiTech’s consistent pursuit of innovation is also evident in specific projects, such as the recovery of hydrocarbons from used rubber products and the development of recyclable materials for automotive interiors.

Angelika Anna Kohns

Media & PR Manager

ContiTech