ContiTech Launches Thunderbolt SilentSync® Composite Sprockets to Help Customers Optimize Drive Performance and Reduce System Costs

- Up to 80% weight reduction with corrosion-resistant, customizable composite design

- Expands access to SilentSync™ belt technology while lowering total drive system costs

- Developed and produced in the Americas, Thunderbolt sprockets deliver lightweight, high-performance solutions for today’s demanding applications

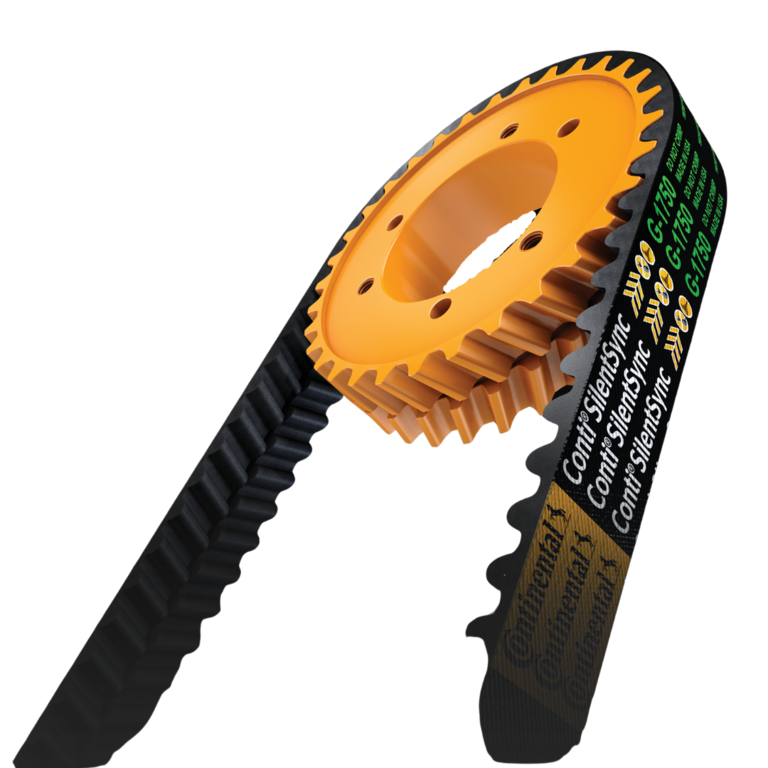

Fairlawn, OH, September 9, 2025. Continental’s group sector ContiTech has announced the launch of its groundbreaking Thunderbolt SilentSync® Composite Sprockets, a next-generation solution set to redefine the standards in the power transmission industry to help customers optimize drive performance and reduce system costs. Leveraging advanced composite materials and carbon fiber reinforcement, this innovation delivers unmatched benefits in weight reduction, corrosion resistance, and design flexibility, while expanding access to ContiTech’s acclaimed SilentSync™ belt technology.

Engineered from a patented high-strength material (U.S. Patents 10865868, 10989293, 11015694), Thunderbolt SilentSync® Composite Sprockets offer up to 80% weight reduction compared to steel counterparts, significantly lowering rotational inertia and easing installation, especially in vertical shaft applications. These sprockets are optimized for demanding synchronous belt applications, providing high durability with over 200,000 hours of combined lab testing and five years of successful field operation in industries ranging from HVAC to food processing.

“Our engineering team developed Thunderbolt SilentSync® with real-world challenges in mind,” said Joe Glandorf, Head of Product Management, Power Transmission Solutions, Industrial Solutions Americas at ContiTech. “From energy savings to improved workplace safety, these sprockets deliver real operational value. Whether you're upgrading existing systems or designing new ones, this technology offers an ideal path forward.”

Thunderbolt sprockets, developed and produced by ContiTech in the Americas region and specifically for this region, are currently available in a Helical Offset Tooth (H.O.T.) construction. Future plans include straight tooth profiles as well as large-diameter Thunderbolt sprockets designed for Air Cooled Heat Exchanger (ACHE) applications where the weight savings are very beneficial.

In addition to performance, customization is a cornerstone of the Thunderbolt SilentSync® line. Customers can tailor designs for their unique power transmission needs while benefiting from improved handling, reduced shipping and storage costs, and extended equipment longevity due to lower overhung weight. Combined with the industry exclusive SilentSync® belt technology and performance, the combination of the Thunderbolt sprocket and the SilentSync® belt yields up to 30% less drive conversion cost as compared to drives with traditional metal sprockets.

“This is more than just a product launch. It’s a transformative step toward making high-performance drive systems more accessible, efficient, versatile, and economical,” said Robert B. Jack, Distribution & PTS Marketing Communications Manager, Industrial Solutions Americas at ContiTech. “Thunderbolt SilentSync® empowers users to harness the full potential of our SilentSync™ belt technology with a lighter, corrosion-resistant, and more cost-effective sprocket solution.”

Thunderbolt SilentSync® Composite Sprockets are already being deployed in commercial and industrial applications, and ContiTech’s application engineering team is available to assist in evaluating suitability, life prediction analysis, and design customization.