Biotech Startup Colipi To Filter and Utilize CO2 from Combustion Gas at ContiTech Hamburg

- Colipi will filter CO2 from combustion gas used in steam generation at the production site of Continental’s ContiTech group sector, using it to feed microorganisms

- Colipi GmbH will lease office, research and production space at Continental’s Hamburg-Harburg location

- Using CO2 to produce bio-based materials marks a key step toward industrial carbon capture and utilization (CCU)

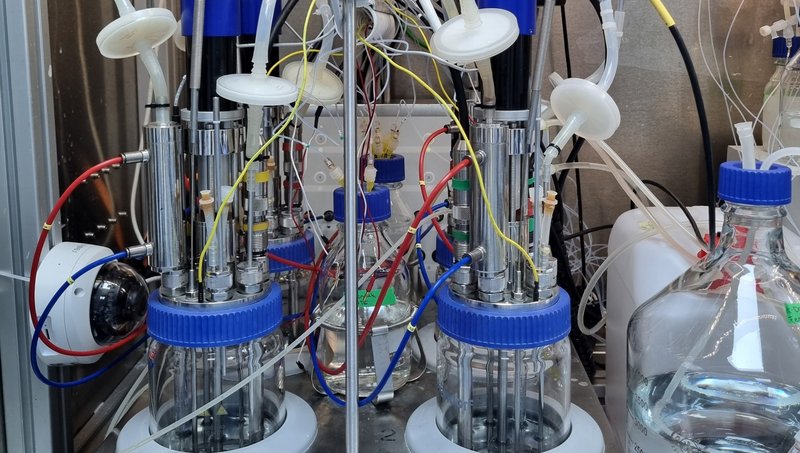

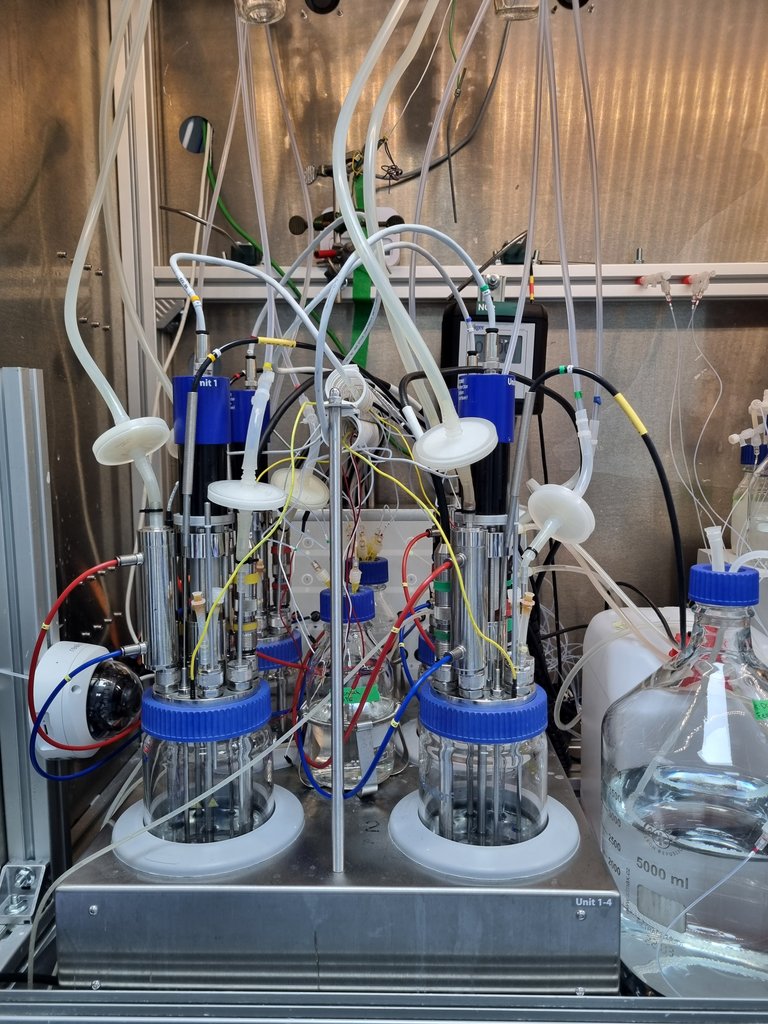

Hamburg, Germany, November 19, 2025. Continental’s ContiTech group sector has partnered with biotech startup Colipi GmbH, which plans to lease space at the ContiTech site in Hamburg-Harburg and use CO2-rich exhaust gases from production to cultivate microorganisms, both starting in summer 2026. The goal of the collaboration is to establish one of the world’s largest bioreactors, where bacteria will convert carbon dioxide (CO2), hydrogen (H2) and oxygen (O2) into valuable biomolecules such as Climate Oil, a sustainable alternative to plant-based oils like palm oil.

Once installed, the bioreactor will receive CO2-rich exhaust directly from the steam generation system at the ContiTech location. This process transforms CO2 into a resource for producing bio-based materials – a major step toward industrial carbon capture and utilization (CCU).

COLIPI reaches milestone in product development

In the summer of 2025, Colipi achieved a major milestone. On August 19, a Colipi team collected exhaust samples from the rooftops of the ContiTech site for lab analysis. The subsequent experiment was highly successful, demonstrating that untreated combustion gas from steam generation does not inhibit bacterial growth. The microorganisms were able to use the CO2 as a carbon source – even in the presence of trace gases such as 46 ppm nitrogen oxides (NOₓ) and 7 ppm carbon monoxide (CO).

These findings highlight the robustness of Colipi’s biological process and underscore a key advantage of biological CCU technologies over chemical-catalytic methods: their tolerance to fluctuations and impurities in exhaust quality.

“As a spin-off from Hamburg University of Technology, we’re delighted to have found a strong partner in ContiTech here in Hamburg-Harburg. Not only are they giving us space to grow, but they’re also contributing CO2-rich exhaust for our field testing, helping us validate our technology for industrial CCU applications,” says Maximilian Webers, CEO and co-founder of Colipi GmbH.

Partnership supports site optimization and carbon footprint reduction

“This collaboration with Colipi is the result of dedicated cooperation with TUHH, Tutech Innovation GmbH and network partners in southern Hamburg, such as the Tempowerk Technologiepark Hamburg,” says Dirk Stuhrmann, head of Continental’s Hamburg location. “We see this partnership as a major step toward carbon neutrality for our site.”

Continental’s ContiTech group sector focuses on industrial products made from rubber, plastic and metal, where material expertise is key. In Hamburg, air springs as well as rubber compounds used as preliminary products for a wide range of industries are produced. ContiTech experts are actively engaged in the shift toward bio-based, carbon-neutral and recycled materials. CCU applications are also relevant for ContiTech’s own operations – for example, products that Colipi plans to produce in Hamburg could be used in ContiTech’s rubber compounds.

Michael Hofmann, head of technology at ContiTech: “We’re working hard to identify and implement CO2-reduction measures at our production sites. The ability to use carbon dioxide productively could be a breakthrough. It turns CO2 from part of the problem into part of the solution. Collaborating with pioneers in CCU – and being one ourselves – reinforces our belief that the perceived conflict between ecology and economy can be resolved through focused research and development in materials.”