ContiTech Air Spring Press Simplifies Installation for Workshops

- New service tool for folding the bellows in on itself and pressing it onto the piston

- Fast, easy fitting without damaging the material

- Ergonomic solution for workshops enhances occupational safety

Hanover, Germany, August 2017. ContiTech has expanded its workshop portfolio. The company is now unveiling its own air spring press for fitting replacement air springs in commercial vehicles. “This helps workshop staff fold the air spring bellows in itself, thereby simplifying the fitting operation on a truck or bus,” says Bastian Dobrick, sales manager for the air springs aftermarket at ContiTech Air Spring Systems.

Up till now, folding the air spring bellows in on itself has been a complicated process requiring both force and experience. To make the air spring bellows the necessary fitting height, workshop staff apply pressure to it manually. That’s no easy task as the bellows often buckles unevenly. At the same time, a great deal of force is needed to fold it in on itself to reach the desired height. Workshops therefore sometimes also make use of home-made tools to achieve the relevant size in the air spring. “However, these home-made tools are not standardized and sometimes do not conform to the current safety regulations,” declares Dobrick.

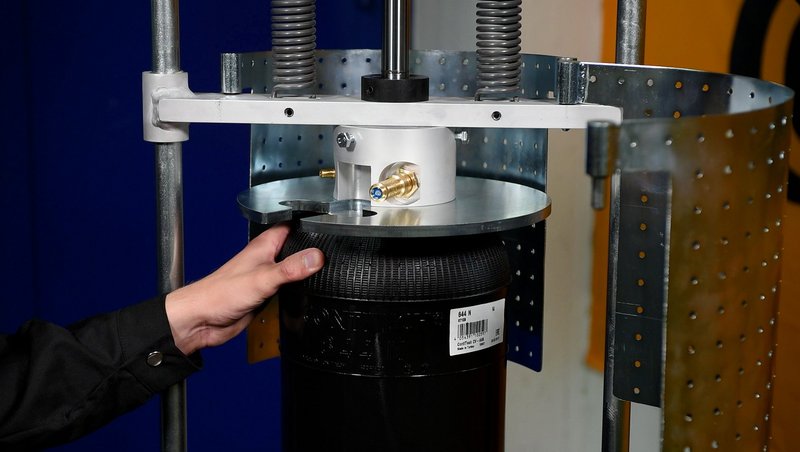

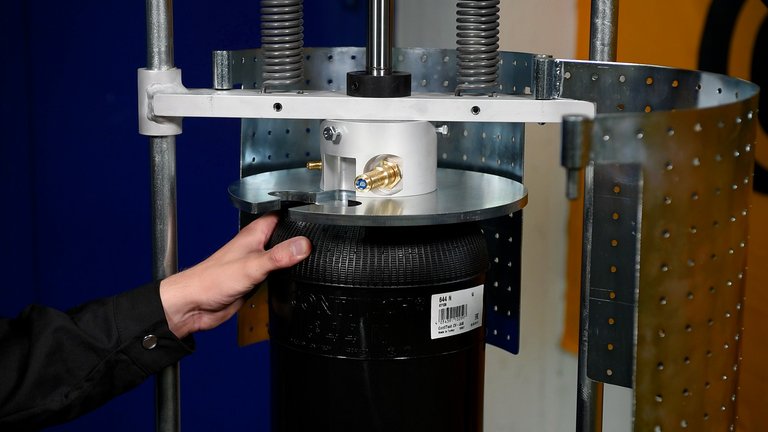

ContiTech has now developed an air spring press of its own to ensure greater reliability and safety for workshops when fitting air springs. It is designed to work with ContiTech, Phoenix and Prime-Ride brands and speeds up the fitting process. Before operating the press, the user selects the appropriate seal plates that are fitted in the press at the top and bottom. The air spring is located on the lower seal plate. The press is positioned on the air spring with the aid of a hydraulic pump. The user then has to connect the compressed air to the press and close the guard before the actual process starts. The hydraulic pump is then operated to ensure that the air spring is folded in on itself uniformly.

Reliable connection with piston

The air spring press also presses the air spring onto a piston. In some cases, the original piston is therefore re-used and fitted to the vehicle together with the air spring. The piston is located on a mandrel in the press for this purpose. The air spring folds over the piston during this process, resulting in a firm connection.

“Our press has been optimized to work for both processes, meaning that damage to the bellows surface is reliably prevented,” says Dobrick. “The new service tool therefore contributes to our air springs achieving a long service life in the vehicle.”

In addition to a high level of process reliability for the air spring, the system also particularly ensures greater safety for the workshop staff. The press therefore enables ergonomic handling without the need for staff to exert great force while at the same time enhancing occupational safety in the workshop.

The new ContiTech air spring press is supplied complete with a hydraulic pump and corresponding seal plates. Workshop owners can choose between a manual and a foot pump and different seal plate sets.

For more information on the new service tool, please visit the company’s following web page www.airspringreplacement.com where you can view a video illustrating the use of the air spring press in detail and also download an information leaflet. A printed version of the brochure is also available free of charge in German, English, French, Italian, Spanish, Portuguese, Polish, Russian and Japanese at airsprings_replacement@as.contitech.de.

Wolfgang Reinert

Head of Media & Public Relations

ContiTech