Being The First Female Electrician in Maintenance

Continental is one of the foreign investors who became actively involved in reintroducing vocational education in the Romanian education system. Our plant, along with Continental Automotive and Contitech, has been a partner of this project since the beginning. It has now reached its fourth generation, due to its long-term cooperation with the Technical Highschool “Regele Ferdinand I.” in Timisoara. From the first two generations (2014 and 2015), all seven graduates have become Continental employees. During their studies, they had their practice periods in our plant. Starting with the third generation, the period of studying has been extended from two to three years, to allow a more in-depth acquisition of knowledge and skills.

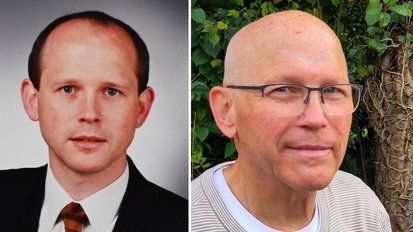

Introducing myself, I should probably begin with my educational background. I graduated from the technical high school Regele Ferdinand I. in Timisoara. Afterwards, I did my practice period at the Continental tire plant from the second generation of the technical highschool. There, I worked in the Final Finish Area. Right after graduation (in September 2015), I was hired as an electrician in that same area. With me, our plant marks a premiere: We are the first of the Continental tire plants to break the ice and have a female electrician in Maintenance.

Generally, the Final Finish Area is responsible for giving our tires a thorough quality check. My tasks as an electrician in Maintenance include making sure that systems like conveyors run smoothly and machines meet the necessary standards. Besides, I am also the one to call when a system breakdown needs to be fixed. When I started at the plant, I was very excited. However, my initial enthusiasm of being an employee at Continental was gradually joined by responsibilities professional tasks bring.

What I like most about Continental is, first and foremost, the organization itself but also the fact that quality requirements are strictly followed.

When I compare being a practice student to being an employee, I have to say that both experiences complement each other. As a practice student, I had the chance to see others at their work and learn from them. As an employee I can now make practical use of all the things I learned. Before I started working there, the Maintenance Electrician Team had been exclusively male. But, nonetheless, I don’t see any differences in comparison to a mixed team. I’m treated as an equal by the colleagues in my shift and I feel like a part of the team. As everyone else, I have my tasks and responsibilities. In my line of work I must, particularly, respect the labor protection regulations, the operating and maintenance specs of the equipment and systems.

One of the challenges an electrician encounters is being creative. Coming up with improvements for electrical systems can be tricky. But this stops being a challenge the moment the electrician has a very good knowledge of the functioning, operating and maintenance of the systems they work with. Personally, especially my graduation project has been a challenge. The topic was: Controlling an Electrical Lamp of 40W (220 V) by Means of a Light Barrier, and Keeping it Lit for a Set Time Period with the Help of a Timing Relay.

At this point, I’d like to take the chance and give my thanks to everyone at Continental for this amazing career opportunity!

Would you like to know more about Dual Cooperative Study programs and Apprenticeships at Continental? Click Here

This article was written by our employee.

Raffaela Micu