Our German Trainees Help – Great Social Commitment During the Corona Crisis

Our trainees help! The Corona pandemic is an exceptional situation for many areas of society – making it even more important for people to support each other. For example our trainees in Germany: Continental released them from work to contribute in social projects. Please read through these great projects, which shows how they live one of our core values #ForOneAnother:

Sarah Tolkmitt, Studies plus Engineering and Mechatronics, Villingen-Schwenningen

I was socially involved during the period of the Corona crisis by sewing protective masks.

When I heard that trainees at Continental can be given time to engage socially during the crisis, I remembered an article in the newspaper. The so-called “Maskenstube”, set up by the German Red Cross located in Villingen, was urgently seeking helpers for sewing protective masks. You can pick up fabrics, mostly old sheets from the hospital, but also donated shirts or other fabrics and will receive instructions on how to sew the masks.

I picked up two large fabrics there and sewed about 40 masks in about two weeks.

The finished masks I could hand in at the “Maskenstube”.

Louisa Knoche, Vocational Training Industrial Business Management Assistant, Korbach

At the beginning of 2020, the circumstances, conditions and fears surrounding “COVID-19”, colloquially known as “coronavirus”, became increasingly acute. Significant changes were also noticeable at our Continental site in Korbach. From now on, many employees carried out their work from home. But for the majority of our production employees, the possibility of a “home office” was out of the question. A new concept had to be developed to protect the people who were on site despite the pandemic.

Within a very short time a part of the office space was converted into a mask production with various stations. Separate cutting, ironing, sewing and packaging room were set up. In addition, a sewing team consisting of ten sewing enthusiasts was put together. I was part of these dedicated helpers in addition to my training. My tasks included cutting the fabrics to the desired sizes, packaging, shrink-wrapping the masks and carrying out the final inspection. Here, small beauty corrections were made, e.g. cutting off excess threads. Finally, the daily count was carried out.

Working in a team gave us all great pleasure, as we all wanted to achieve the same goal: To produce enough protective masks for our colleagues to be able to give them more security. This motivation was also reflected in the production figures. At the beginning, we were still pursuing the goal of producing five masks for each of our 3600 employees in order to be supplied for one working week. Soon we went far beyond this goal – our production figures increased almost daily! We are happy to have produced more than 35,000 masks especially for our site.

The production of protective masks at the site in Korbach will continue for the time being. At present, replacement masks are needed for our staff, as there are considerable signs of wear due to daily use.

Thanks to the skills acquired in the production of the masks, I have also started to produce various masks privately for my family and friends, together with my family. Our aim was to support and protect especially those people who do not have the possibility to sew their own masks or to purchase masks due to the shortage of supply. I am proud to have been part of this project.

Franziska Listl, Vocational Training Industrial Business Management Assistant,

Regensburg

At the start of the hop season, no seasonal workers were able to enter our country or only under conditions that could hardly be fulfilled. That is why I chose my holiday wisely to help my parents clean/tie up hops on my days off, after work and in my free time. These days were physically very exhausting, but they were a healthy change from the office routine. The work lasted a total of 14 days, but there is still a lot of rework to be done, according to the motto “Hops want to see their master every day”.

As no workers were able to enter the country, friends and family helped so that we could manage the work in the time frame. Unfortunately, many people do not know that this work is crucial for the harvest in August/September. If there were no volunteers this year, the harvest for 2020 but also for the next years would not be good, because this work is extremely important for a hop vine for the current year and for the growth of the following year.

With this commitment I would like to support agriculture and the food chain, as beer should not be taken for granted in Bavaria. There is a great deal of manual work involved in this product.

Everything is of course done under the recommended protective measures. For example, we work at least 2 meters apart and the common meal is divided into different rooms and shifts so that a safe distance is guaranteed. My commitment is probably different from that of the other trainees, but I think that in times of Corona, people are often forgotten who do their best to produce our food for everyone.

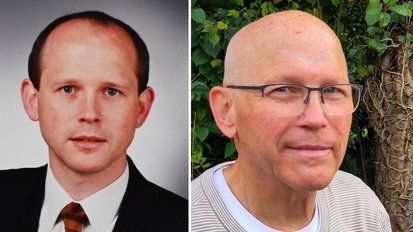

Johannes Höfling und Sven Reitz, Vocational Training Mechatronics, and Gökhan Cevrim, Retrainee Mechatronics, Babenhausen

To support local institutions such as nursing homes, pharmacies and doctors, we are currently producing face shields in our training workshop. We supervise the 3D printers (partly private printers) with 2 trainees and a retrainee and assemble the shields afterwards. For the visors we use foils from the factory’s own Heads-Up-Display production, which were cut to size in the punching shop. The shields have already been distributed to 2 nursing homes for elderly people, 3 doctors, a social welfare organisation and the social centre in Babenhausen.

It was frightening for us that almost all stations expected that they would have to pay something in return for the shields. Unfortunately, this shows once again that someone is always trying to make a profit out of the situation.

Tobias Doderer, Dual Student Mechatronics – Project Engineering, Schwalbach

I have been active in the fire department since 2017. Among other things, I head the radio department of the Eschborn fire department. Within the scope of this department, I and my team had to take care of the introduction of a new cloud solution at the beginning of the crisis, so that all departments of the Eschborn fire department could work together online, i.e. exchange files and hold online meetings.

In addition, one day in March I drove through the area by truck and bought enough beds to be able to accommodate the emergency department in the fire station in case of quarantine – that’s perhaps a funny story.

Basically, not much has changed from the point of view of operations, but the work around it has become much more extensive and complicated. In addition, we are constantly asked to minimize our social contacts, to work in our home office and not to meet each other personally, if this is avoidable, in order to minimize the risk of having large parts of the emergency department not available at the same time.

This article was written by our employee.

Leah Berking