Ashes of Risotto Rice Husk in Tires: Continental Focuses on More Sustainable Fillers

- Tire manufacturer prioritizes use of renewable and recycled materials

- Silica from rice husk ashes is a particularly resource-saving raw material

- More sustainable carbon black is obtained from bio-based sources and through recycling

- Jorge Almeida, head of Sustainability at Continental Tires: “Innovation and sustainability go hand in hand at Continental. Using silica from the ashes of rice husks in our tires shows that we are breaking completely new ground – without compromising on safety, quality or performance.”

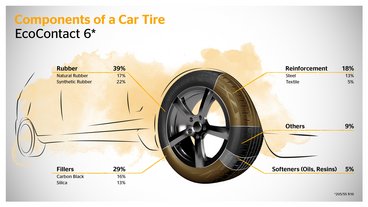

Hanover, Germany, July 8, 2025. Continental is increasingly focusing on renewable and recycled materials in its tire production. While the share of these materials averaged 26 percent in 2024, the tire manufacturer expects an increase of two to three percentage points in 2025. By 2030, the share of renewable and recycled materials in Continental’s tire production is set to rise to over 40 percent – while maintaining consistently high safety and performance standards. Carbon black and silica play a crucial role in this transformation because, alongside rubber, they make up a large proportion of the raw materials in tire production. Both are fillers that make the rubber, for example in the tire tread, resistant and are also responsible for essential tire quality characteristics such as grip and braking performance.

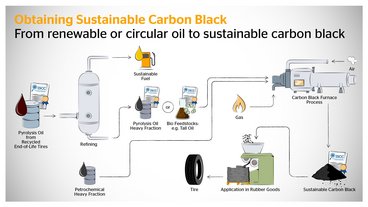

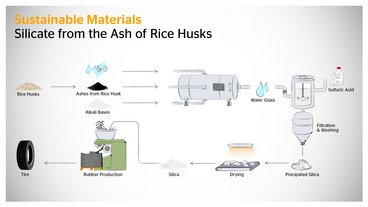

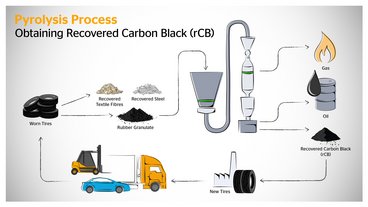

Continental obtains both materials in proportion from recycled or renewable sources in order to reduce resource consumption. Silica, a filler required to achieve optimal grip and reduced rolling resistance, can be obtained from rice husks instead of quartz sand. The husks are an agricultural by-product from the production of risotto rice, for example. For the raw material carbon black, Continental relies on three innovative processes. Firstly, carbon black can be produced from bio-based alternatives such as tall oil, a waste product from the paper industry, instead of crude oil. Secondly, it can be produced from recycled raw materials such as pyrolysis oil from end-of-life tires. Thirdly, a particularly efficient pyrolysis process enables the recovery of carbon black directly from end-of-life tires.

“Innovation and sustainability go hand in hand at Continental. Using silica from the ashes of rice husks in our tires shows that we are breaking completely new ground – without compromising on safety, quality or performance,” says Jorge Almeida, head of Sustainability at Continental Tires.

Silica: a more sustainable raw material from the ashes of rice husks

Continental is increasingly using silica variants derived from the ashes of rice husks across its whole tire portfolio. Rice husks are an agricultural by-product of the Asian agricultural industry and Italian risotto rice production. This type of silica is manufactured by Solvay in Italy, among others. Innovative processing methods are used to turn this agricultural by-product into silica. The method of production from biomass is more energy-efficient than conventional production processes. Silica from rice husk ash thus supports the circular economy and contributes to a more sustainable value chain. Traditionally, the raw material is obtained from quartz sand. Silica has been an important complement to carbon black as a filler in many tire rubber components for around 30 years – Continental was an early pioneer of this innovative technology. Silica has revolutionized the safety and energy efficiency of tires and played a crucial role in reducing braking distances by almost 50 percent. Just as importantly, using silica in tread compounds helps to reduce rolling resistance and therefore energy consumption and CO2 emissions. This highlights how the use of a more sustainable material such as silica in Continental’s tire production can have a positive effect along the value chain.

Bio-based and recovered carbon black for more sustainable tire production

Carbon black offers great potential on the path to more sustainable tires. Accounting for up to 20 percent of the total weight of a passenger car tire, it is one of the key fillers used in tire production. It is essential for the strength of the rubber and therefore responsible for the durability of the tires. Around a dozen different types of carbon black from suppliers such as Orion Engineered Carbons and Tokai Carbon are used by Continental during tire production. For example, different carbon black is used for the stability of a tire's sidewall than for the rubber compound of the tread, which requires special strength due to the forces acting on it while driving. One solution is the use of bio-based carbon blacks, which are derived from organic oil rather than crude oil. These so-called sustainable carbon blacks can be produced from bio-based raw materials like for example tall oil. Another process relies on recycled raw materials. For instance, more sustainable carbon black can be obtained from recycled pyrolysis oil derived from end-of-life tires. This carbon black can be used as an alternative to fossil oil. In both cases, Continental uses the mass balance approach. This approach replaces a defined proportion of fossil raw materials with bio-oils or recycled pyrolysis oil. These alternative materials are allocated to the end product on the balance sheet, eliminating the need to adapt existing production processes.

In addition, Continental has joined forces with Pyrum Innovations, a specialist in the reprocessing of end-of-life tires using thermolysis technology, to further optimize and expand the recycling of end-of-life tires through pyrolysis. This process extracts the carbon black from the end-of-life tires and prepares it for reuse in new tire production. So far, the recovered carbon black – a mixture of various types – has been used by Continental in the production of forklift tires. Continental and Pyrum Innovations are currently working on new processes to make the recycled carbon black usable for further tire applications in accordance with the relevant performance and safety requirements.

Henry Schniewind

Head of Global External Communications

Continental Tires