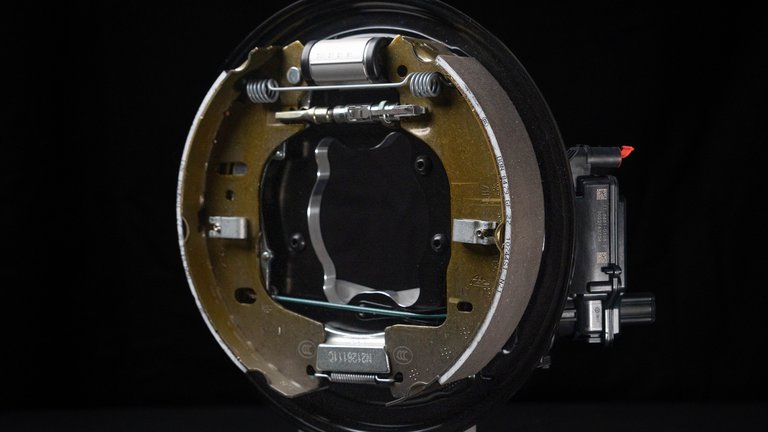

Electric parking brake with Lightweight Drum

Innovation accelerates the Drum Brake Revival and makes a proven technology fit for the future

This is where we come from: Drum brakes from Continental are as much well-proven as they are innovative. Simplex drum brakes, for instance have a long track record of extremely reliable low-maintenance operation. In the changing automotive industry with a strong focus on electrification, emission reduction, comfort and uncompromised safety, Continental drum brake innovation makes the strengths of this mature brake design available in modern, highly efficient and clean vehicle concepts – by adding new strengths to drum brake technology.

One element of that is integrating a state-of-the-art electric parking brake function into the hydraulic service brake. In the current EPB-Si (Electric Park Brake for Simplex brakes) generation the parking brake is actuated by a small DC motor that applies the brake shoes. This design can be found, e.g., on the rear axle (RA) of the VW ID platform, e.g., the ID.3/.4 models.

+++ High level of comfort +++ Massively reduced weight +++ Minimized brake dust emissions +++ |

Why drum brakes are beginning to experience a revival

The drum brake as such offers three major benefits for electrified and clean cars.

- Firstly, the frequency of wheel brake actuation is much lower in an electric vehicle: 80 % and more of the deceleration events are typically covered by running the electric machine in its generator mode. This Win-Win situation of harvesting kinetic energy to generate power and to decelerate the vehicle can be used to deliver up to 0.3 g of braking effect. On the flip side of the coin, this means the wheel brakes are only activated very rarely in an electric vehicle as long as an energy-efficient driving style is used. Now, the closed design of the drum prevents corrosion on the surface of the brake’s grey cast friction ring. Thus, the brakes will reliably offer the same level of performance, irrespective of long periods of inactivity. So, this mature design is actually highly future-proof.

- Secondly, the drum brake is inherently very efficient due to its design. As the brake shoes are always actively retracted by a spring after braking, there is almost no residual torque which is a big advantage in an electric vehicle as this helps to maximize range. As a disc brake often has a residual torque of around 1 to 2 Nm, integrating a drum brake could save around 1to 2 g of CO2 per kilometer.

- Finally, brake dust remains inside the drum brake. This is particularly relevant to conventional and hybrid cars where the wheel brakes are applied more often, and brake dust emission is getting critical attention. The EPB-Si for instance, meets Euro 6 requirements for PM10 dst (based on actual engine limits) and already performs very close to the estimated Euro 7 requirements. Even this can be met with only minor changes. Further optimization work is under way.

This is where we are going: New Strengths in the EPB-Si Pipeline

Ongoing Hydraulic Brake Systems development work will add two more bonus points to the EPB-Si:

- The electric parking brake is actuated via a highly efficient motor-gear-unit further reducing the power demand. The braking force is constantly applied without power by a self-locking mechanism in the gear.

- The drum’s new lightweight design reduces the brake mass by around 35 %! This brings the EPB-Si with Lightweight Drum close to the mass of a caliper and disc brake.

In all electrified vehicles the power for an electric parking brake is readily available, so this function is also a perfect match for electrified cars. However, another big future benefit of Continentals drum brake technology is already in the pipeline: The Lightweight Drum design will massively reduce the drum brake’s weight.

The lightweight drum consists of two parts: The friction ring is manufactured from standard grey cast and thus offers the optimum tribology. The front plate of the housing, however, is made from aluminum. By using the heavy grey cast only where it is actually needed, bigger drum brake designs become possible. Up to now, the design-related weight of drum brakes limits the feasible brake diameter. The Continental Lightweight Drum will be able to change that by taking out around 35 %of the brake mass. The attractive look of an aluminum housing front is another bonus point of the lightweight drum, even if the actual brake is invisible because of the closed rim design motivated by aerodynamics.

This lightweight design and the low drag torque characteristics are obvious benefits for electrified vehicles because less weight and high efficiency translate into a longer range – or a smaller battery without impacting the range.

Current experience with the innovative EPB-Si suggests that the EPB-Si design in general will prove to be a lifetime component (delivering 300.000 kilometers and more) not requiring any maintenance in an electric vehicle on the RA, while it will probably not require more than brake shoe replacement in a conventional or hybrid car.

Bottom line: Innovated drum brakes such as the EPB-Si are an intelligent technology with high potential for wider use in efficient cars.