It Just Keeps on Saving Fuel: The eHorizon Cracks the One Billion Liter Mark

- The sensor system has saved more than one billion liters of diesel and three million tons of CO2 in truck traffic since 2012

- Information from the eHorizon helps to optimize other system functions

- Next generation analyzes traffic flow and can save up to two percent more fuel

Frankfurt, June 6, 2019. Since 2012, trucks equipped with the static eHorizon from the technology company Continental have saved over one billion liters of diesel – or the equivalent of nearly three million tons of CO2.* “The static eHorizon is proof that the right product conserves resources in the cost-driven truck industry. This investment not only pays off for truck manufacturers but is also helping the environment”, says Gilles Mabire, Head of Commercial Vehicles & Aftermarket at Continental.

Around 410,000 commercial vehicles are equipped with the static eHorizon today. Continental works with a total of ten truck manufacturers, including numerous well-known companies from Europe, Asia and the USA – and the company expects further growth in the near future, particularly in North America. “The US market is picking up strongly,” explains Mabire.

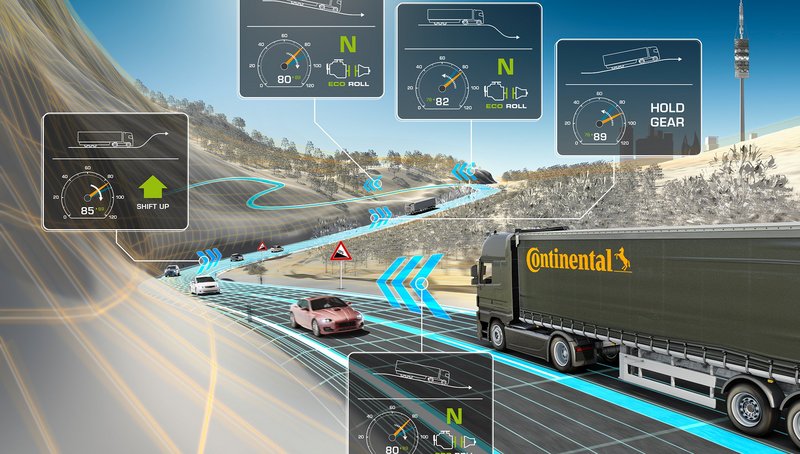

The static eHorizon delivers information about the condition of the route ahead to the ECUs in the vehicle, based on highly precise topographical route data from the location cloud developer HERE Technologies and GPS signal information. The ECUs then automatically adapt driving style and speed.

Aftertreatment of exhaust gases, energy recovery and co. – exploiting more saving potential

Adaptive cruise control or predictive transmission control to avoid unnecessary gear changes are not the only applications that commercial vehicle manufacturers can implement with the sensor system. “Customers can also use the information from the eHorizon to optimize other system functions like the exhaust gas aftertreatment and increase their potential savings even more,” explains Dr. Raimund Varnhagen, Head of Product Management eHorizon, Telematics and Automated Driving for Commercial Vehicles at Continental. This is usually done by simply updating the software of the relevant algorithms.

The list of possibilities is long, and includes the optimization of heat recovery and exhaust gas aftertreatment, since the ideal time for particle filter regeneration can be calculated based on the eHorizon data for the route ahead. This prevents the energy-intensive process from being interrupted and having to be repeated, which occurs, for example, if, the engine requires a lot of additional power on a steep hill. Additionally, the rear axle oil pressure can be regulated automatically to minimize oil losses, and the air conditioning system can be used efficiently for thermal energy recovery. The combination of just a few applications like this also significantly adds to a reduced fuel consumption.

Next generation reduces fuel consumption by another two percent

The next generation of the electronic horizon, the so called dynamic eHorizon, offers an additional savings potential of up to two percent compared to its predecessor. In this expansion stage, the digital map material is updated in close to real time through networking with the cloud, providing accurate and fresh data on the current traffic situation. Since the driving behavior can be adapted to the current traffic situation at an early stage, this not only increases safety, but the eHorizon also becomes an important basis for automated driving. Continental is currently testing the dynamic eHorizon in various predevelopment projects specifically for commercial vehicles.

* The exact values are 1.13 billion liters of diesel and 2.98 million tonnes of CO2' . They are based on modeling by Continental, which takes into account not only the annual mileage and fuel consumption per truck, but also the number of vehicles delivered.

Christopher Schrecke

Media Spokesperson Safety and Motion

Continental Automotive