Caoutchouc – the metamorphosis of a key raw material for Continental

As a raw material, caoutchouc has decisively shaped both Continental’s identity and its 150-year history. This raw rubber was so central to production that it was originally even found in the company name: Continental-Cautchouc- & Gutta-Percha-Compagnie.

But the raw material was and is not only of great importance for Continental: Caoutchouc also significantly determined the production possibilities in the entire rubber industry. As a result it was the focus of global trade for a long time. This made the raw material a seismograph for the political and economic development of the past 150 years.

In the 19th century, caoutchouc was extracted almost exclusively in Brazil. In Germany, however, it was initially considered an exotic raw material. However, the global consumption of caoutchouc quickly increased and with it its importance for production. The problem was that the world trade market for raw rubber was still dominated by a few British trading companies at that time. These tried to influence prices in their favor through market interventions and supply reductions. In addition, the raw materials for the rapidly developing rubber industry were subject to unusually large price fluctuations at that time.

In order to make itself less dependent on the strong price fluctuations and the associated potential supply bottlenecks, the Continental Executive Board pursued several strategies: In 1895, Continental founded its own trading company in Peru. This company used, among other things, a steamer with the name “Continental” for the transport of raw rubber, which, however, sank a year later together with the cargo. A later attempt to obtain a direct supply of raw rubber was initially tabled. Instead, Continental took a stake in 1908 in a Brazilian company for the extraction of caoutchouc.

In order to ensure the supply of raw materials, Continental relied on recycling at an early stage: In 1903, a factory for the reprocessing and recycling of used rubber was opened in Seelze near Hanover. With this step, Continental laid the foundation for its sustainability strategy. The company has expanded and further developed this with numerous other measures to the present day.

In order to become more independent of the global caoutchouc trade, Continental participated in the first attempts to produce synthetic rubber in 1906. However, the First World War was accompanied by a double upheaval in Continental’s raw material situation: On the one hand, there was a drastic transition from wild to plantation caoutchouc, accompanied by changed quality and processing requirements. On the other hand, Germany was largely cut off from the caoutchouc supply at that time.

With the end of the war, Continental’s supply of raw materials improved again: Germany was now again present in the world’s most important caoutchouc trading centers and also re-entered international trade.

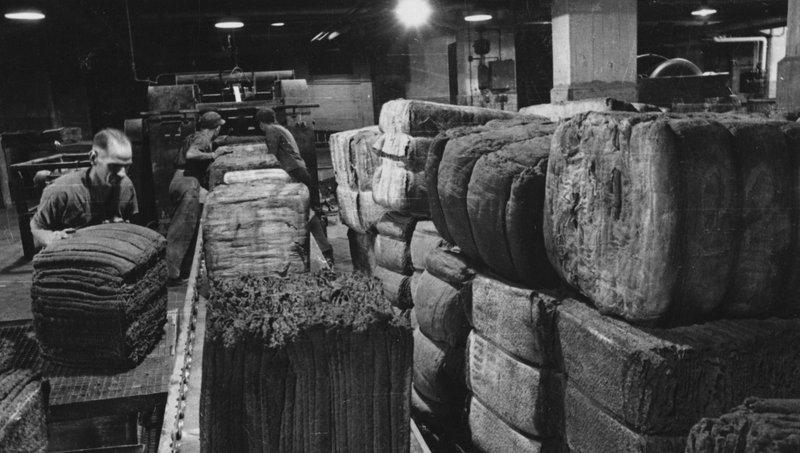

When caoutchouc prices fell in 1929, the site for the recycling of old rubber was moved from Seelze near Hanover to Hanover-Limmer. The supply of caoutchouc then reached a record high: In 1929, Continental consumed 13,000 tons of natural caoutchouc – almost four times as much as in the last pre-war year. Within two months, the same amount of raw rubber was consumed as in the whole of 1913.

At that time, 144 railway wagons full of raw caoutchouc headed for the raw material warehouses in Hanover every month. In addition, there were 35 railway wagons with cotton fabric, almost 600 wagons with coal and 17 wagons with gasoline. To produce 83,000 car tires from this also took 44,000 metric tons of steam and 3,989 million kilowatts of electricity. For that time, these were impressive figures – not only for Continental’s financial accountants, but also for the entire industry.

In the following period, the caoutchouc trade again fell into the vortex of political events: The Nazi regime converted the German economy into a substitute material economy, which pushed the development of synthetic caoutchouc (“Buna”). Due to the significantly higher price, the Continental Executive Board initially reacted skeptically to the use of synthetic caoutchouc. In the end, however, this was integrated into production without objection – in accordance with the wishes of the Nazi regime.

After the end of the war, price increases and scarcity limited the import of raw materials, massively endangering the restoration of competitiveness.

In the following decades, the proportion of synthetic caoutchouc increased more and more. This helped to at least partly cushion the further price fluctuations for natural caoutchouc. Nevertheless, numerous global political tensions and conflicts again influenced the supply of raw materials: For example, Continental clearly felt its dependence on petroleum as a raw material as a result of the oil price crisis in the 1970s.

In order to be less dependent on the international supply of raw materials overall, Continental therefore planned its own caoutchouc plantation in Indonesia in 1980. However, this project was soon put on hold again in view of the high risks in terms of capital investment and investment security.

Another consequence of the oil crisis: Germans’ environmental awareness grew strongly in the 1970s. Continental also increasingly invested in measures to increase sustainability in production. In 1977, for example, the company installed a new cooling water circuit system at the Vahrenwald plant. This eliminated the previous consumption of potable water for cooling the machines. Two years later, the Limmer plant was also equipped with air filter systems to neutralize the exhaust air from worn tire recycling.

Finally, in 1992, a comprehensive concept was developed for an environment-oriented corporate strategy. As a result, in 1994 – in addition to the factory for the reprocessing and recycling of used rubber in Hanover-Limmer – a separate recycling company for tires was founded. In the 1990s, Continental succeeded in enormous further development of its early sustainability ideas from the 20th century.

By the beginning of the new millennium, Continental had further professionalized its procurement management. Life cycle assessments showing the environmental impact over the entire product life cycle became the standard in all plants. Continental has been pursuing a profound integration of raw material management, environmental policy and sustainability goals since 2006, after which a new perspective on caoutchouc purchasing and the associated supply chain management also emerged. Almost 15 years after its launch, the Continental environmental management system of 1992 was further developed and refocused. From then on, environmental protection was explicitly understood as an integral part of operational management tasks and embedded in a comprehensive management system.

A specially created business area “Quality and Environment” monitored compliance with the principles of resource conservation and employee commitment to environmental protection. The same applies to the consideration of the ecological impacts across all the value chains and throughout the entire product life cycle. The business division also ensured that the operational environmental relevance in production was also pursued throughout the Group.

In the following years, two approaches helped Continental to adjust its raw material supply: First, caoutchouc from the Russian dandelion has been used industrially since 2007 as part of the Taraxagum project. Secondly, in 2018, the defined sustainability factors were also extended to supply chains. As a result, Continental established a binding “Continental purchasing policy for sustainable natural caoutchouc” for the procurement of raw materials. With the integration of the sustainability aspect into the procurement processes, existing codes on ethical, social and ecological aspects were expanded and subjected to greater verifiability.

Looking back, it is once again clear what significance the upheavals in the supply of raw materials had for Continental – especially in caoutchouc. However, it also shows how much continuity runs through the history of the company: From sensitivity to price fluctuations to politically induced dependencies in the procurement of raw materials. Caoutchouc and raw material procurement has always been a very demanding task at Continental – this was just as true in 1880 as it was in 2020.

At the same time, however, it also becomes clear how the company’s natural caoutchouc procurement policy has developed over the decades into holistically oriented, sustainability-oriented, complex resource management. Not only has the technical utilization of caoutchouc changed, but also at the same time the awareness of this raw material. In addition to caoutchouc, other important raw materials were added over the decades, so that Continental has long since removed the former main raw material – and not only from its name.

Even so, caoutchouc is still of great importance for Continental: In 2019, natural caoutchouc still accounted for 37 percent of total caoutchouc consumption, while synthetic caoutchouc accounted for 63 percent.