Continental Presents New Solutions for Future 48 Volt Hybrid Architectures

- The first production applications of the Continental 48 V Eco Drive from 2016 mark the start of a new phase of mild hybridization

- Starting from an arrangement using a 48 V starter generator (BSG) in the engine's belt drive, future 48 V architectures will be integrated at an increasingly higher level.

- The potential for saving fuel increases with each level of integration, because energy management can make more comprehensive use of the alliance between the internal combustion engine and electrical energy.

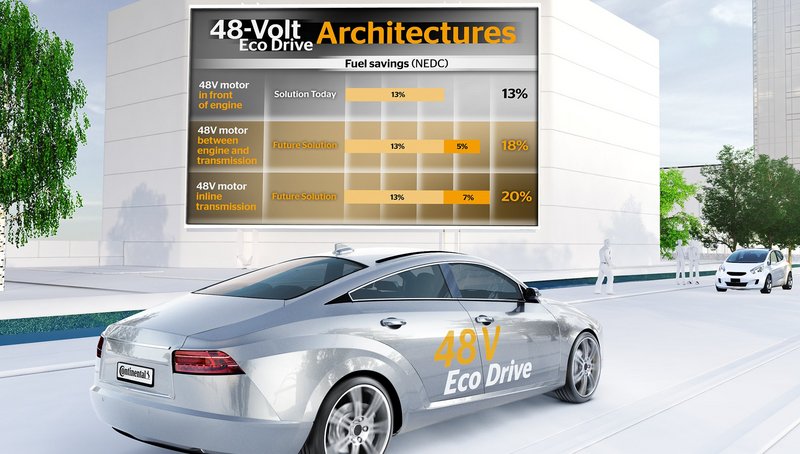

Frankfurt, Regensburg, September 15, 2015. The international automotive supplier Continental is already developing solutions for future 48 V hybrid architectures. The integration of a second voltage level of 48 V into the vehicle will enable significant progress in CO2 emissions. The 48 V architecture that integrates the starter generator into the engine's belt drive (Belt Starter Generator, BSG), which can be implemented at only modest expense, has already demonstrated savings of 13 percent in the New European Driving Cycle (NEDC). Hybrid driving strategies make an even greater difference in inner-city traffic, where savings of around 20 percent are possible. Several customers will already be introducing this 48 V Eco Drive into production in 2016.

José Avila, Member of the Executive Board at Continental AG and Head of the Powertrain Division, stated: "In the future, the demands on 48 V technology will increase even more. The aim will be to achieve even greater efficiency benefits with less installation space and weight while keeping costs the same. The integration architecture of a 48 V system can make a big contribution here. That is why we are developing other 48 V architecture solutions for the period after 2020."

In general, 48 V systems are about much more than just the integration of components. Decisive for the amount of fuel that can be saved is, when the energy is recuperated as well as when and how the electricity is used. Only when all aspects of an entire system are considered – vehicle propulsion, direct CO2 savings, partitioning of the 12 V and 48 V networks including their consumers, and exhaust gas aftertreatment – the interplay between internal combustion engine and electrical energy can be comprehensively optimized. “48 V technology goes far beyond electric power," was Avila's summary.

More highly integrated architectures extend energy management and create additional fuel consumption benefits

Continental is working on other new solutions for future applications. For example, in collaboration with Schaeffler, Continental has developed a prototype module named P2-BSG with 48 V BSG and integrated belt drive, which is constructed for side-mounting between internal combustion engine and transmission. The module is slated to be ready for volume production starting in 2020. By adding a second coupling in front of this module, the BSG can be driven by the belt, without the internal combustion engine having to be dragged along too. Dr. Oliver Maiwald, Head of Technology & Innovation in the Powertrain Division, explains: "Because no drag losses occur, recuperation produces more energy which is then available for fuel-saving driving strategies. This architecture will therefore probably save another 5 percent of CO2 on top of the existing savings."

Parallel to this, Continental is working on a third integration level that goes even further. The starter generator, which is fully integrated between engine and transmission (Inline Starter Generator, ISG), will probably be ready for use from 2025. Compared to the second integration level, this full integration in the P2-ISG arrangement will offer the potential to cut fuel savings by a further 2 percent because there will no longer be any friction losses due to the belt.

Of course, the greater the energy efficiency of a 48 V hybridization during recuperation phases, the greater is the degree of freedom in energy use. In addition to the electric torque support, new and existing high level consumers of electricity (such as A/C compressors) can be transferred to the 48 V system using more highly integrated future architectures. The 48 V system provides the necessary energy and the components will work even more efficiently because of the higher voltage level.

For example, these new 48 V consumers could also include Continental's new electrically heated catalyst (EMICAT®), which heats the catalyst structure within fractions of a second, as soon as the combustion engine is restarted after an idle phase (start-stop, coasting). "In the future, it will become ever more important to define the right users for the energy generated from recuperation. The real skill with 48 V is the operating strategy," says Maiwald.

Simone Geldhäuser

Head of Media Relations & Press Spokesperson Innovation & Technology

Vitesco Technologies

- +49 941 790-9961302