Continental Thermal Management Increases Vehicle Efficiency by 25 Percent

- Extended range and less charging time for electric vehicles

- Less emissions: high-performing thermal management necessary to meet future emission regulations under RDE conditions

- Mass volume production start for an electric vehicle is scheduled to take place in China end 2019

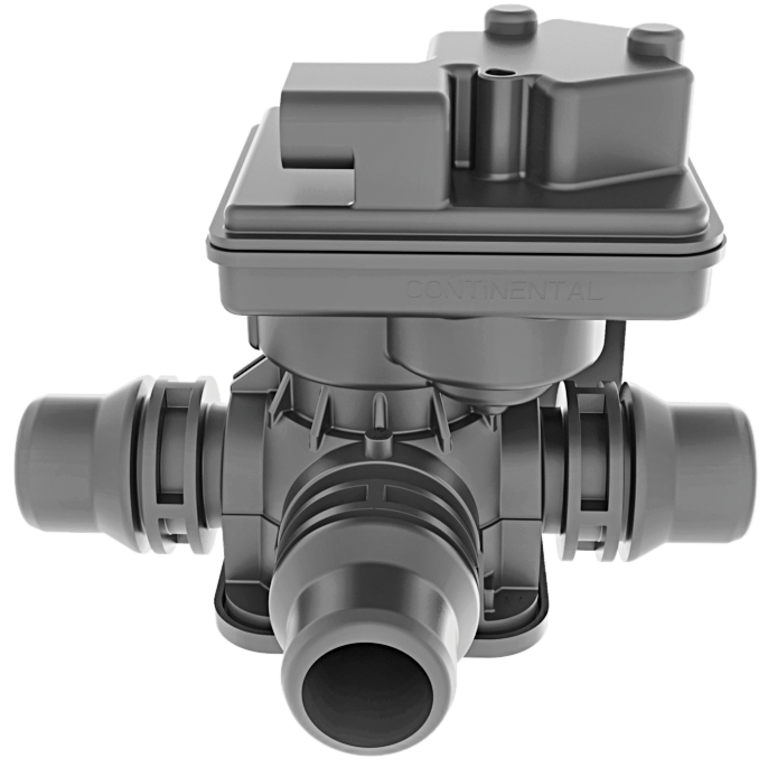

Regensburg (Germany), Shanghai (China), September 20, 2018. At the Global Future Mobility Conference 2018 in Hangzhou from September 20-23, 2018, the technology company Continental will be showcasing intelligent thermal management solutions for future vehicles. Current owners of electric vehicles or hybrid cars can hardly avoid this experience: In the winter or in the summer the electric range of their vehicle is considerably lower because the electric energy for heating and cooling is also taken from the battery. Owed to this phenomenon the range can decrease by as much as 40 % at -10 °C, for instance. The technology company Continental utilizes cross-divisional know-how to compensate this range loss to a large extent. Existing and new products make it possible to control the need for heating and cooling within the entire vehicle in a more energy-efficient way. Thermal Management (TM) is the instrument used for this end. Its components form a flexible modular set which allows it to switch thermal energy flows for heating or cooling to where they are needed while avoiding losses. New multi-port valves called Coolant Flow Control Valves (CFCV) serve to flexibly switch heating and cooling circuits in a way to route available heat or cold to the right places.

„Thermal Management is increasingly relevant to all vehicle types because it improves efficiency and thus helps to achieve core development targets such as minimizing CO2 and reducing emissions“, said Klaus Hau, Head of Sensors & Actuators Business Unit, Powertrain division of Continental. „However, the ultimate challenge to Thermal Management is the electric vehicle where the focus is on increasing range even during cold or hot ambient temperatures.“

First Thermal Management products are already in production. The start of production of a first TM volume order for an electric vehicle is scheduled to take place in China towards the end of 2019.

Benefits With and Without Combustion Engine

Thermal Management is a long-established function in vehicles with combustion engine. It serves to rapidly heat up of the engine to its optimum temperature thus ensuring a clean and efficient operation. Also, an efficient engine will only deliver little waste heat for other purposes because that is a direct outcome of good thermodynamic efficiency. Finally, the exhaust gas after-treatment has to be instantly available under all operating conditions in the interest of emission safety. Extended engine-off phases in a hybrid car provide an example. To achieve this goal, the optimum temperature span has to be controlled in the exhaust tract at all times – while saving fuel. Without a high-performing TM, meeting future emission regulations will therefore be a true challenge under real driving conditions (RDE). „The combustion engine will also depend more strongly on a high-performing Thermal Management“, concludes Peter Biber, Head of Sensors & Actuators Business Unit China (S&A).

As there is no combustion engine supplying heat in the electric vehicle, heating and cooling fully depend on electric energy. Compared to a car with combustion engine, TM is more demanding in an electric vehicle as there are many individual spots such as motor(s), battery, and power electronics which require either heat or cold depending on the operating condition. For instance, a Li-Ion battery can only accept recuperated energy if it the battery warm enough for it – however, not too warm either! During rapid charging it is important to protect the battery against over-heating to avoid a de-rating of the charging current that would translate into longer charging times. TM in an electric vehicle therefore requires several multi-port valves and water pumps as well as sensors plus a suitable network of lines and hoses to route heat and cold to where they are needed under a specific operating condition – with the aim to protect the battery state of charge. „This is another benefit of TM. If I have to recharge less frequently and to a lesser degree this will increase the service life of my battery“, Biber adds.

„It is the goal of our comprehensive Thermal Management to maximize the range also in the winter and in the summer season. Assuming a specific case we think it is feasible to increase the winter range of an electric vehicle by around 25 %“, says Biber. „This is facilitated by an Intelligent Thermal Management that optimizes all thermal flows through applying a comprehensive understanding of the total vehicle system“.

Simone Geldhäuser

Head of Media Relations & Press Spokesperson Innovation & Technology

Vitesco Technologies

- +49 941 790-9961302