3. Circular Economy

By 2050 at the latest, and together with all of its partners in the value chain, Continental wants to make the idea of a circular economy a reality and fully close all product and resource cycles. Circular economy will be the economic model of the future. Because, as philosophy professor Michael Thompsons explained in his book Rubbish Theory back in 1979: There is no such thing as waste – just material in the wrong place.

Circular economy can help to make finite resources infinitely usable, thereby sustainably shaping the economy for the growing and increasingly prosperous world population. Consumer electronics are a prime example of the inconsistencies that the world is currently grappling with: Billions of people across the world use them for work, to do their shopping, communicate with one another and for many other purposes besides. And yet production of these electronics is hugely resource-intensive and gives rise to risks associated with the consumption of scarce resources. Redesigning value chains in accordance with the principle of circular economy offers a solution to this challenge: From the engineering of devices that are easy to repair to the use of robots that disassemble these at the end of their useful life and recover the components within so that they can be reused, closing the product cycle for a device offers enormous potential for sustainable economies. The European Union in particular is putting its weight behind the creation of a sustainable circular economy with its EU Circular Economy Action Plan.

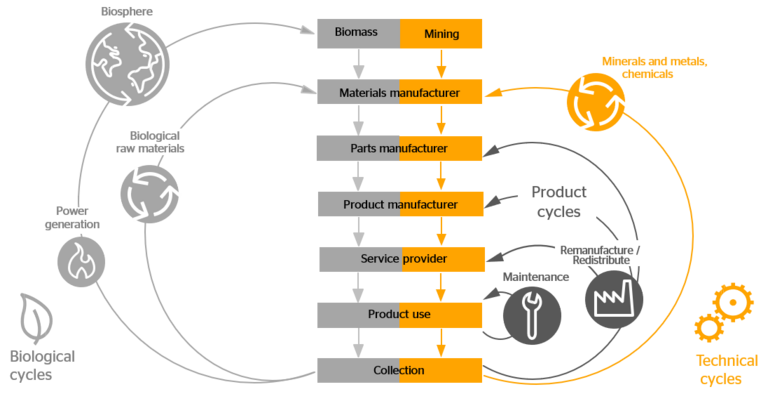

A total of three cycles are the key to avoiding the need for new materials:

Companies that anticipate this disruptive development and take the lead will be able to hugely benefit from it. This requires a complete redesign of many products with the aim of recovering resources from these. This is accompanied by a shift to new business models.

Worldwide, around 90 billion metric tons of raw materials of all kinds are currently consumed each year in order to keep the global economy going. Some studies even estimate this figure at almost 500 billion metric tons if we factor in excavated material. The recycling model that is generally applied today is a small step in the right direction, but ultimately is still not enough. After all, recycling means that most materials lose their quality in the longer term, increasingly limiting how they can be used. Current recycling methods can therefore only be viewed as a transitional solution. Ultimately, these will need to be replaced by more effective solutions.

A fully circular economy is an ambitious vision with many challenges involved in making this a reality. Continental’s commitment in this area at an early stage as well as the development and shaping of this transformation provide a competitive edge for a forward-looking company.

For operational waste management, Continental has set itself the target of increasing its waste recycling rate to 95 percent by 2030. The waste recycling rate measures the proportion of waste that has been recycled by external service providers or has undergone material recycling, recycling for energy recovery, or recycling of any other kind.

Back to overview sustainability.